The 4T Ultimate with Patented ER2 Groove Design has a number of features that set it apart from the competition. Clutch kits are comprised of a cover assembly, clutch disc, release bearing, spigot bearing, and alignment tool (some kits also include a solid replacement flywheel or DMR). The cover assembly is finished with a premium corrosion-resistant surface finish that has excellent oxidation resistance over time. Furthermore, the clutch pressure plate features 4T Ultimate’s ER2 design technology.

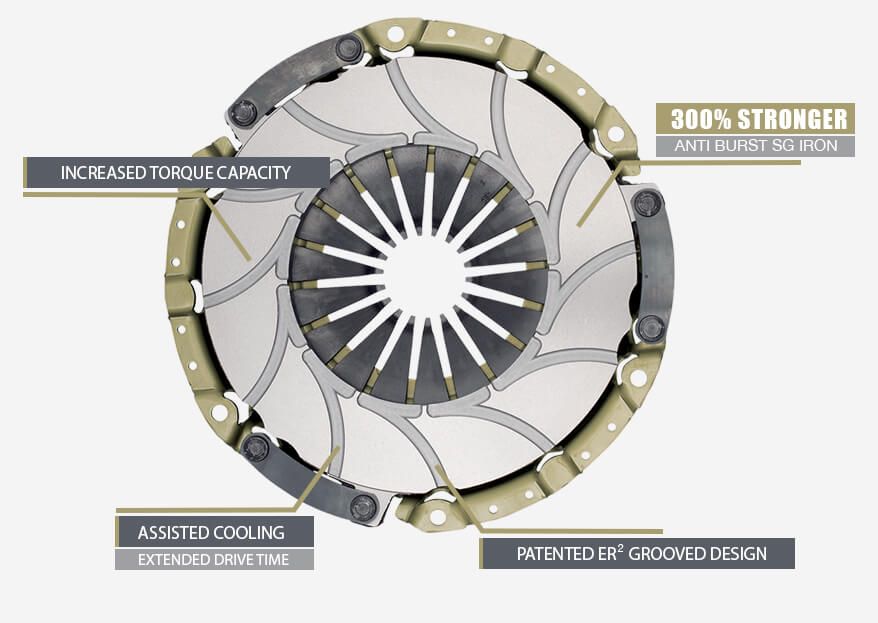

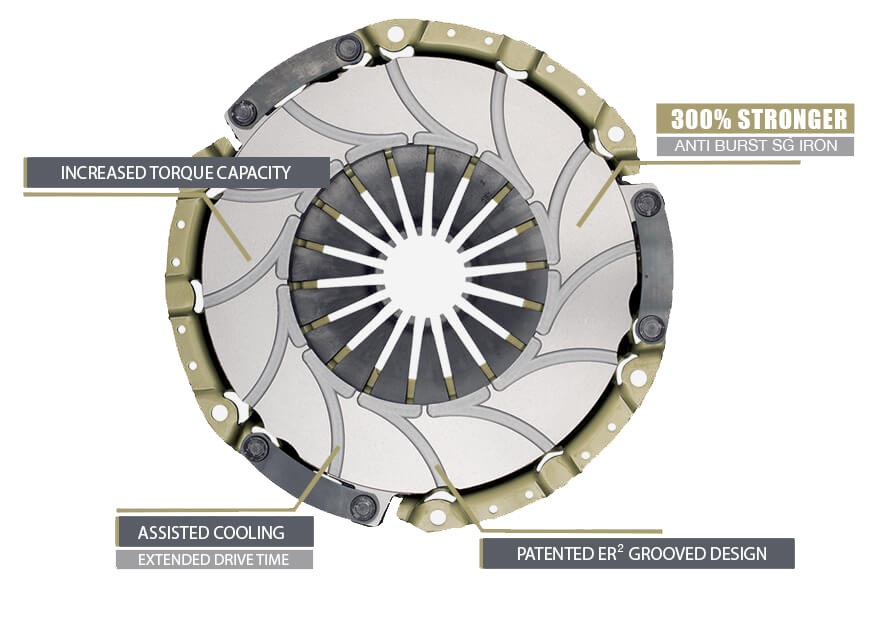

The cover assembly is made of Spheroidal Graphite casting material, which has a yield strength 300 percent higher than standard castings. Heat dispersion is also improved by the material’s microstructure. The clamp load on the cover assembly is higher than on a standard cover assembly, resulting in increase torque capacity.

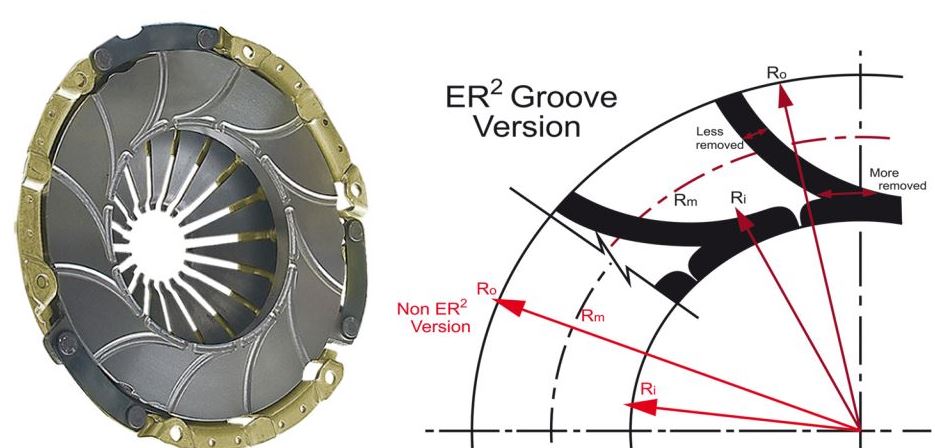

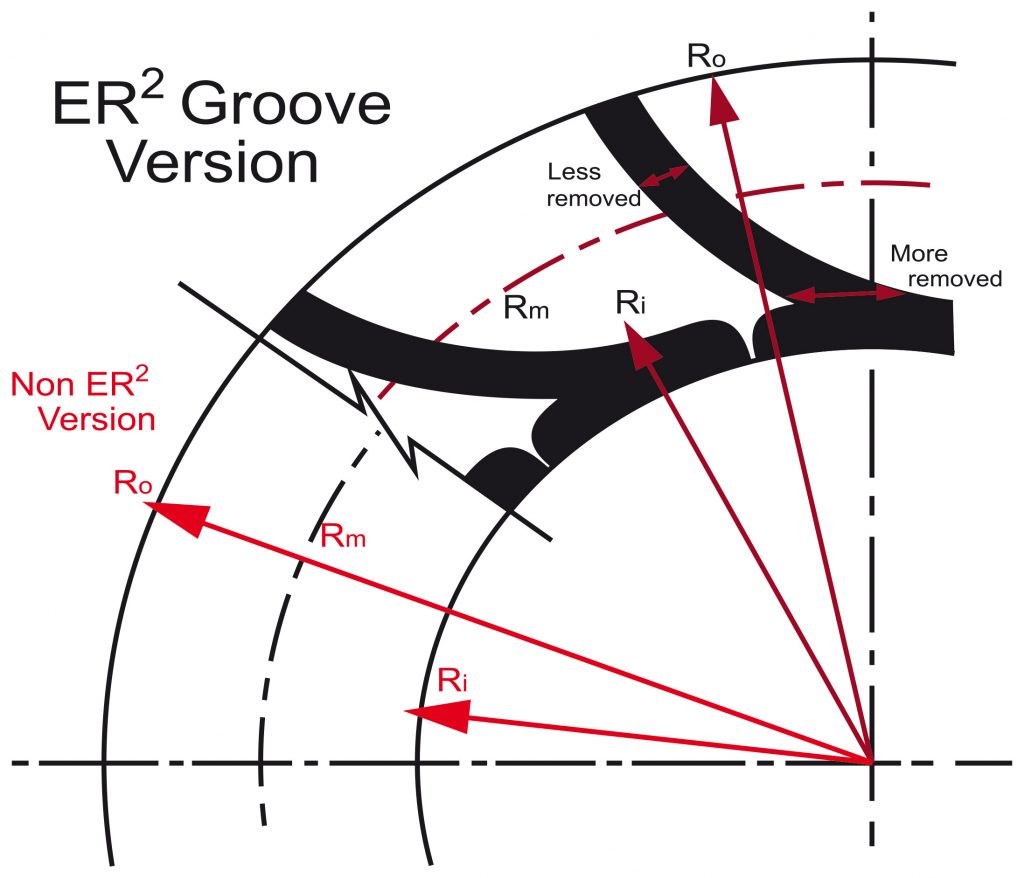

CAD/CAM technology is used to precision machine the patented pressure plate with ER2 grooves. In two ways, the design improves performance. First, it increases the torque capacity by increasing the mean effective radius, and second, it aids in cooling, allowing the friction material to operate at lower temperatures and thus with a higher coefficient of friction.

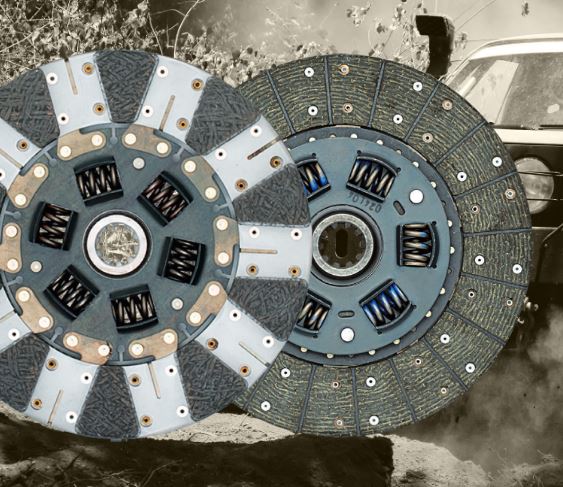

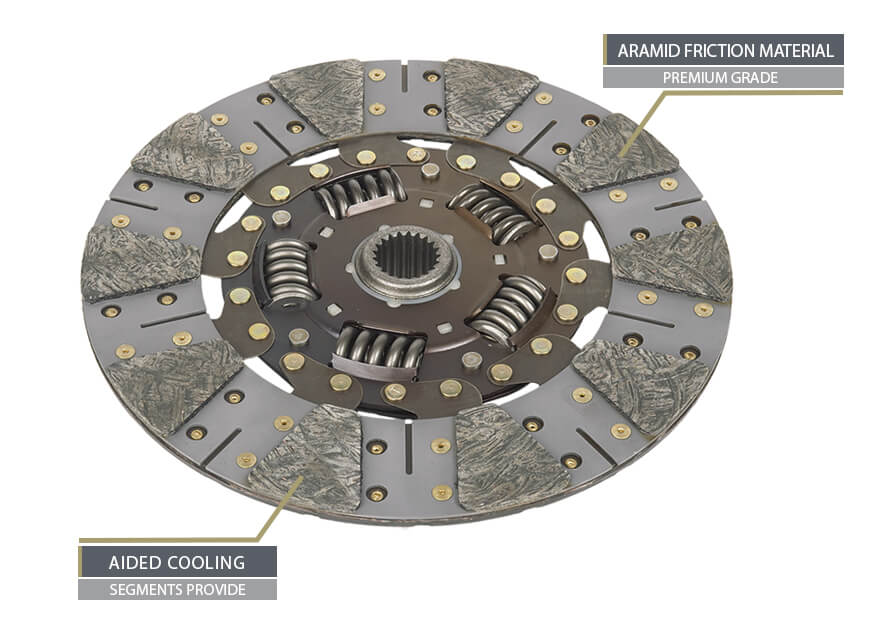

A special flywheel side friction layer is used on the clutch disc. This Aramid friction material has a higher coefficient of friction to increase the torque capacity while not negatively affecting driveability. Clutch fade is also lessened by 50% through the use of this material.

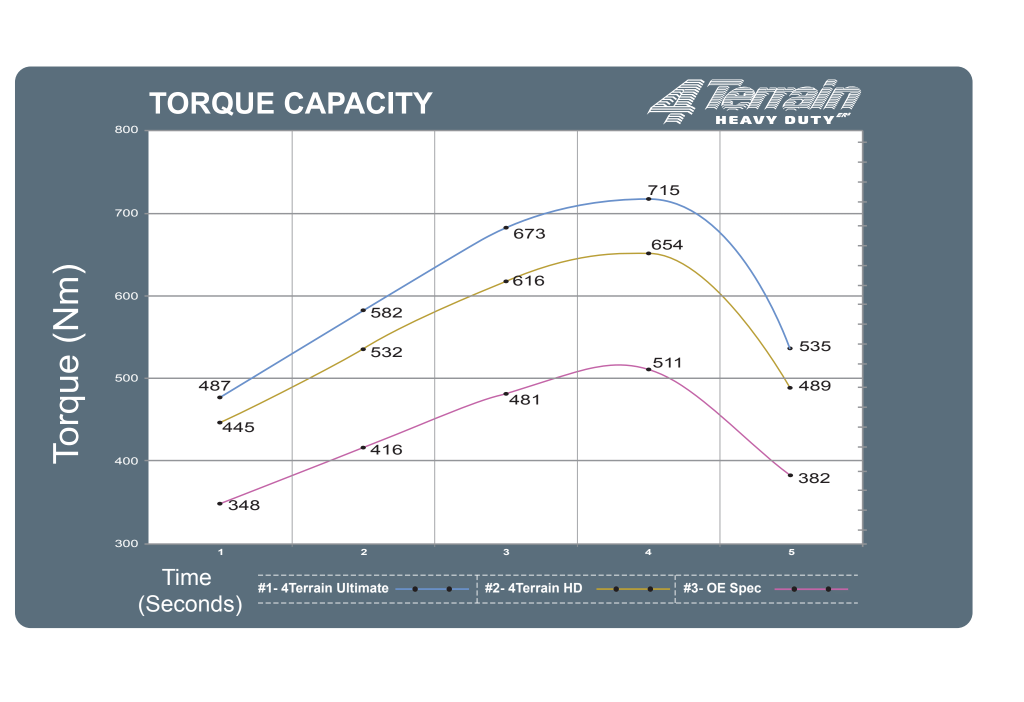

These features ensure that the clutch system can transmit up to 60% more torque than a conventional Clutch Kit, making it appropriate for high-torque applications. Higher clamp loads, a larger Mean Effective Radius of the pressure plate, improved cooling, and a higher coefficient of friction materials on the clutch disc have all contributed to this increase in overall torque capacity.

The 4Terrain Ultimate is the perfect clutch for any extreme off-road vehicle, backed by a 3 Year/50,000Km warranty.